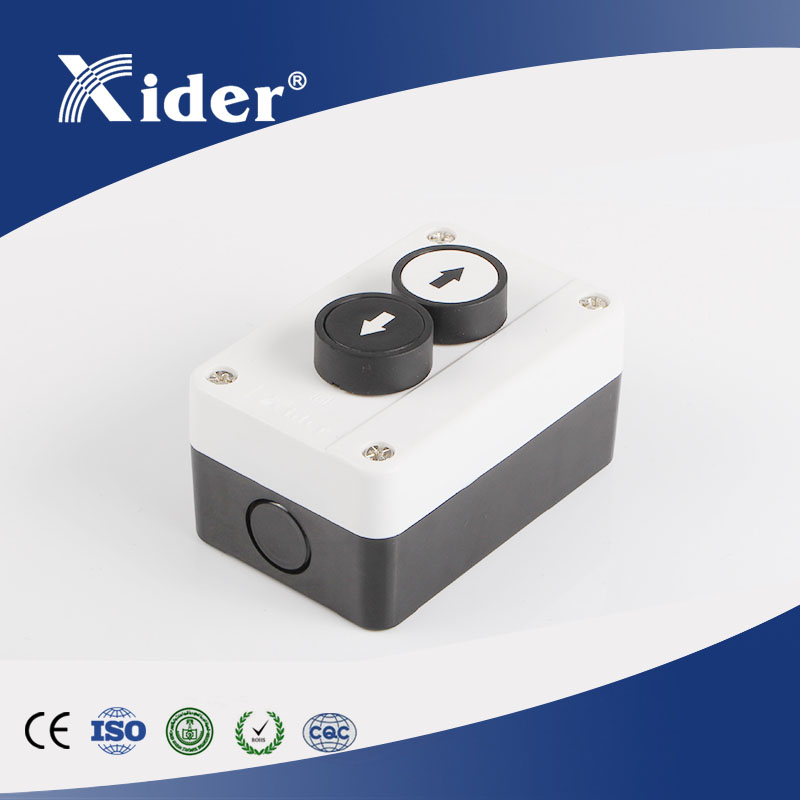

A control box is an enclosed unit housing electrical or electronic components designed to manage and regulate the operation of machinery, systems, or processes. It serves as a centralized hub for control, protection, and communication within various applications.

Basic structure and core components

Enclosure

Material: metal, plastic or fiberglass, with dustproof, waterproof, explosion-proof and other characteristics.

Design standard: follow the protection level to ensure stable operation in harsh environments.

Control and operation components

Input devices:

Buttons (start/stop, mode switching), knobs (adjusting parameters), touch screens (human-machine interface HMI).

Sensor interface (connecting sensors such as temperature, pressure, position, etc.).

Control core:

PLC: commonly used in industrial scenarios, realizing logical control through programming.

Microcontroller/single-chip microcomputer: used in small systems, such as home appliance control boxes.

Relays, contactors: control the on/off of circuits, drive motors, valves and other actuators.

Output devices: indicator lights, buzzers, terminal blocks.

Protective devices: circuit breakers, fuses, surge protectors.

Electrical connection

Terminal block: standardize cable connections for easy maintenance and expansion.

Cable entry: sealed design to prevent dust and water vapor from entering.

Core skills and principles of electrical control box design

In the design of electrical control boxes, following systematic design logic and industry best practices is the key to ensuring functional reliability, safety and economy. The following are the core design points:

1. Define Requirements & Purpose

Functionality: Clarify the control box’s role (e.g., industrial automation, home appliances, machinery control). List required components: switches, buttons, displays (LCD/LED), connectors, circuit boards, relays, etc.

Environment: Specify operating conditions (temperature, humidity, dust, vibrations, exposure to chemicals or moisture). This determines material selection and protection level (e.g., IP65 for dust/water resistance).

Size & Installation: Measure space for the box (mounting location: wall, panel, machine surface) and ensure access for wiring, maintenance, and component installation.

Standards & Compliance: Adhere to safety standards (e.g., UL, CE, IEC) and industry regulations (e.g., electrical codes for wiring, EMC/EMI requirements for electromagnetic compatibility).

2. Drawing design: ensure the accurate correspondence between physical layout and schematic diagram

Core requirements: Draw detailed and accurate electrical schematic diagrams and three-dimensional physical layout diagrams simultaneously at the beginning of the design to ensure that the two are completely consistent in key information such as circuit connection, component location, and terminal numbering.

3. Compliance design: strictly follow safety standards and heating component specifications

Specification compliance: deeply understand and implement national electrical specifications, UL certification standards, and localized safety guidelines for target markets, especially focusing on the installation spacing, heat dissipation design, and material flame retardant rating of heating components.

Risk avoidance: reduce safety hazards such as electrical fires and leakage through compliance design to ensure long-term stable operation of the control box.

4. Component selection: Focus on "applicability first" to avoid over-design

Minimalistic principle: Start with basic components that meet functional requirements, and give priority to solutions with simple structure, easy maintenance and controllable costs. For example:

If the logic control only requires switch input and output, a relay module can be used instead of PLC

In simple status monitoring scenarios, use a combination of indicator lights + buttons instead of complex HMI screens.

When designing a control box, it is necessary to clarify functional requirements, select a reasonable layout, standardize wiring identification, and integrate safety protection and test verification.

XIDER specializes in the production of buttons, indicator lights, control boxes and other low-voltage electrical appliances. If you need to buy a control box, please contact us.