Industrial Push Button Switches are built to withstand tough industrial use, but they don't last forever. Waiting too long to replace a failing switch can lead to unexpected machinery downtime or even safety risks. This article outlines clear, easy-to-spot signs that tell you when it's time to swap out your old switch for a new one.

Doesn't Work Consistently

The most obvious sign of a failing switch is inconsistent performance. If your Industrial Push Button Switch only works sometimes—for example, you press it once and nothing happens, but it works on the second or third try—this means the internal contacts are likely worn or dirty. Over time, these contacts lose their ability to connect properly, and cleaning them (a temporary fix) won't solve the problem long-term. Once the switch starts acting unpredictable, replacement is the safest choice to avoid sudden failures during operation.

Visible Wear or Breakage

Physical damage to the switch is another clear signal to replace it. Check for cracks in the outer shell, a button that's stuck in the “pressed" or “released" position, or loose parts (like a button that wiggles more than usual). Even small cracks can let dust, moisture, or debris into the switch's interior, which speeds up internal damage. A broken or stuck button also makes the switch impossible to use correctly—trying to fix physical damage (like gluing a cracked shell) often doesn't restore full functionality, so a new switch is necessary.

Overheating

An Industrial Push Button Switch should never feel warm or hot when in use. If you notice the switch is heated after pressing it (even lightly), this points to a serious issue—either the switch's electrical ratings don't match your machinery (causing overload) or the internal wiring is faulty. Overheating can melt the switch's internal components or even start small fires in extreme cases. Don't ignore this sign: stop using the switch immediately and replace it to prevent damage to your machinery or safety hazards.

Unusual Noises

Strange noises coming from the switch are a red flag. A healthy switch makes a clear, quiet "click" when pressed. If you hear buzzing, crackling, or see small sparks when using the switch, this means the internal contacts are arcing (creating small electrical sparks). Arcing wears down the contacts quickly and can also damage the machinery's electrical system. This isn't a problem you can fix with cleaning—arcing usually means the contacts are too worn to function safely, so replacement is needed right away.

Conclusion

Knowing when to replace an Industrial Push Button Switch is key to keeping your machinery running and your workspace safe. Watch for inconsistent function, physical damage, overheating, and unusual noises—these signs mean the switch can no longer perform reliably. Replacing it promptly will save you from costly downtime and potential safety issues.

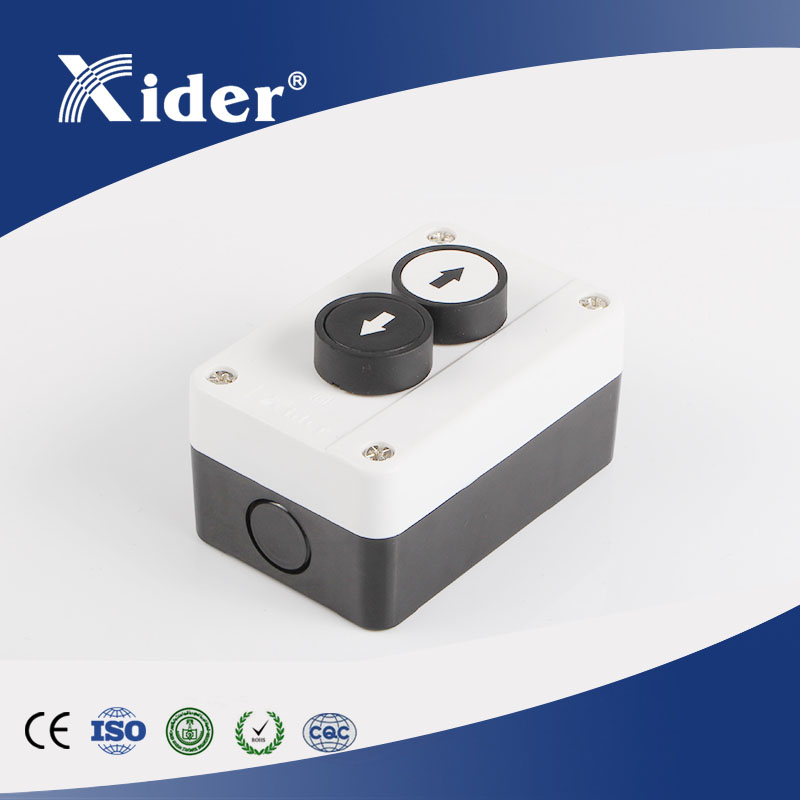

If you're in need of a new, durable switch to replace your failing one—whether you need a standard model or one designed for harsh environments—our product page has a range of options built for industrial use. Head over to explore switches that fit your machinery's needs and keep your operations on track.