Push Button Switch installation precautions

1、Buttons installed on the panel should be arranged neatly and reasonably, for example, from top to bottom or from left to right according to the sequence of motor start. Adjacent

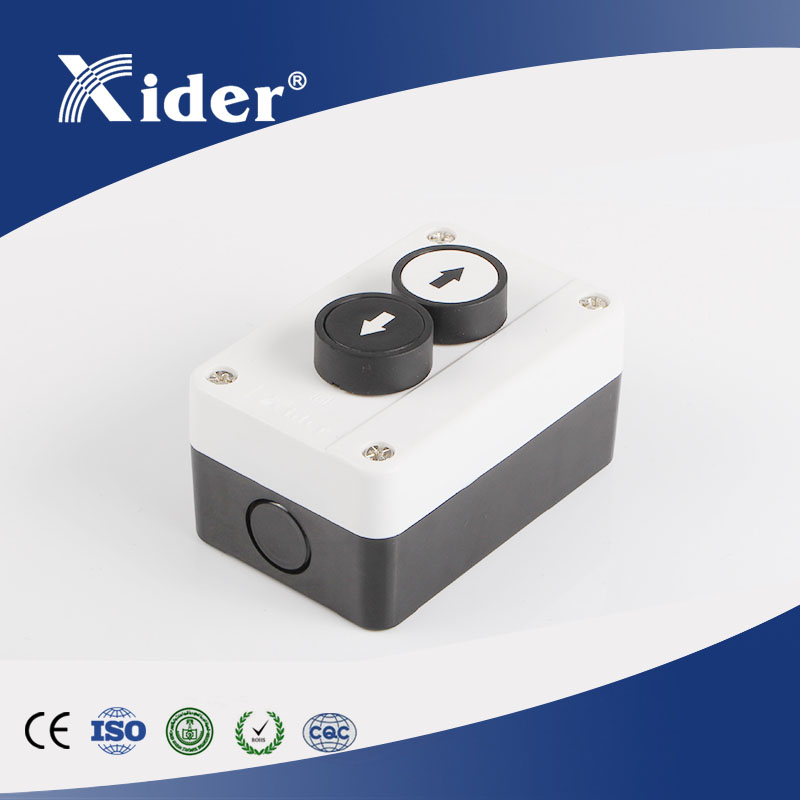

The distance between the buttons is 50~100mm.

2, the same - several different working states of equipment components (such as up, down, before, after, left, right, loose, tight, etc.) should make each - the opposite state of the button installed in a

group. Apply the red button to stop, green or color to start or energize, do not make a mistake.

3, in order to cope with emergencies, when more buttons on the panel, the total stop button should be installed in a conspicuous and easy to operate place, preferably with a red mushroom head button or do

Clearly marked.

4、Because the distance between the button contacts is small, such as oil and other prone to short-circuit failure, so the contacts should be kept clean.

5, the installation of the button plate and button box must be metal, and try to make them and the machine total ground bus connection, for hanging buttons must have a special grounding

Ground wire, do not borrow the metal tube as a ground wire.

6, button for high temperature occasions, easy to make plastic deformation aging and lead to loosening, causing a short circuit between the wiring screws touching each other, can be added at the wiring screw J set of insulating plastic tube to

prevent short circuit.

7、Button with indicator light bulb heat, long-term use is easy to make the plastic lampshade deformation, should reduce the lamp voltage to extend the service life.

8, "stop" button must be red; "emergency stop button must be red mushroom head type; "start" button must have a protective ring, protective ring should be higher than the button head, to prevent

Accidental touch to make the electrical equipment misoperation.