Company Profile

XIDER electric co.ltd, specialized in producing low-voltage electrical appliances, such as push button, indicator light, electric switch and etc. Our company provides ace products and service for our customers in electric power, mechanical, traffic, and industrial automation field and so on.

XIDER electric Co., Ltd engaged in developing and manufacturing low-voltage electrical appliances since the company founded, we introduced the high technology of signal lamps: AD22 series and push buttons of DB2-B/E, DB4-B, DB5-A, DB7-E, XAL-D and developed these products. XIDER holds “exquisite button, create XIDER brand” as our service ideal and developing aim, the company brand and enterprise image strikes root in the hearts of the people and projects. Now the company has set up a perfect sales network throughout the nation, and the products are far sold to Europe, America and southeast Asia.

Office Phone:+86-577-61723801

Mobile Phone:15158476179

Email:julia.yefan@xider.cc

product description

Warning lights are generally used to maintain road safety. They are usually used in police cars, engineering vehicles, fire engines, ambulances, maintenance management vehicles, road maintenance vehicles, tractors, emergency A/S vehicles, mechanical equipment, etc., machinery, electricity, Control signals interlocking in electrical control circuits such as machine tools, chemicals, telecommunications, ships, and metallurgy.

installation method

1. Remind the riders who installed this warning light: the warning light is divided into positive and negative poles, the positive pole is connected to port 58 and the negative pole is connected to the screw, otherwise it will not flash.

2. Be careful when opening T73-A. Due to the small space, students with bad waist should not worry, take it slowly! How to see the photo specifically.

3. the normal wiring method, wiring, one end connected to the screw, one end broken line connected to 58 port, once again broken line cross wiring, only normal flashing.

4. The long row warning light is correctly connected: the red line of the megaphone is connected to the input of the engine, the positive black line is connected to the negative input of the engine, and the normal flashing mode: the yellow line and the white line should be flashed, then the blue line is connected to the horn speaker. , male busbar connector control flashing module.

5. the small warning light is generally connected to the red line corresponding to the battery positive, the black line corresponds to the battery negative, in addition to the halogen rotating warning light

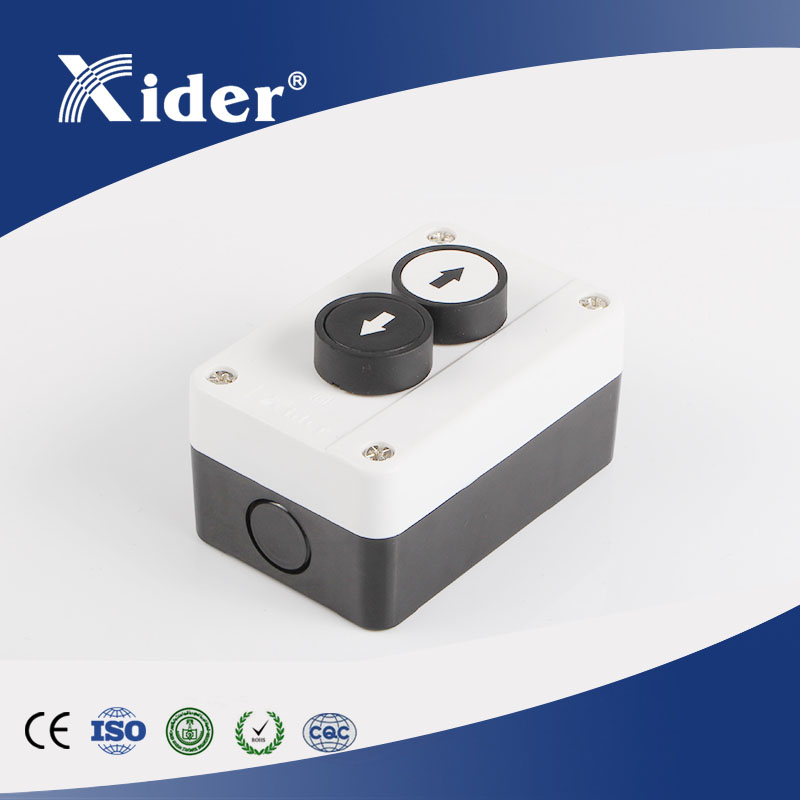

There are many types of push button switches, which can be divided into ordinary button type, mushroom head type, self-locking type, self-resetting type, rotary handle type, with indicator light type, illuminated symbol type and key type, etc. Button, i button and different combinations. Generally, it adopts a water-storage structure, which consists of a button cap, a return spring, a static contact, a moving contact and a casing. It is usually made into a composite type, and has a pair of normally closed contacts and normally open contacts, and some products can pass. The series connection of multiple components increases the number of contact pairs. There is also a self-contained button that automatically holds the closed position when pressed, and can be turned on after the power is turned off.

In actual use, in order to prevent misoperation, different marks are usually made on the buttons or painted with different colors, and the colors thereof are red, yellow, blue, white, black, green, and the like. Normally red means "stop" or "dangerous" operation; green means "start" or "on". The emergency stop button must use the red mushroom head button. The button must have a metal guard ring and the retaining ring should be higher than the button cap to prevent accidental actuation of the button and cause malfunction. The button plate and button box of the mounting button must be metal and connected to the mechanical main ground bus.