Pushbutton switches are among the most ubiquitous and versatile components in modern electronics and industrial systems. These simple yet essential devices play a critical role in controlling circuits, enabling users to interact with machines, appliances, and systems with a single press. This article explores the fundamentals of pushbutton switches, their functionality, types, applications, and their advantages and limitations.

1. What Are Pushbutton Switches?

A pushbutton switch is a type of electromechanical device that is designed to control an electrical circuit by the simple act of pressing a button. These switches are commonly used in a wide range of applications, from simple household appliances to complex industrial machinery. The basic structure of a pushbutton switch typically includes a button, a spring, and electrical contacts. When the button is pressed, it activates the contacts, either making or breaking an electrical connection, and when released, the spring returns the button to its original position.

2. How Do They Function?

The functioning of a pushbutton switch is based on the principle of mechanical activation of electrical contacts. When the user presses the button, it moves downward against the force of the spring. This movement causes the internal contacts to either close (connecting two or more electrical terminals) or open (disconnecting them), depending on the design of the switch. For momentary pushbutton switches, which are the most common type, the contacts remain in the activated state only as long as the button is pressed. Once the pressure is released, the spring pushes the button back up, and the contacts return to their original state. In latching pushbutton switches, however, the button stays in the pressed position until it is pressed again to release, providing a toggle function. This is achieved through a mechanical latching mechanism within the switch.

3. What is the Difference Between Pushbutton and Tactile Switches?

While both pushbutton and tactile switches are activated by pressing a button, there are several key differences between them.

Operation and Feedback

Tactile switches are designed to provide a tactile feedback to the user when the switch is activated. This feedback is usually a "click" sensation, which indicates that the switch has been successfully pressed. Pushbutton switches, on the other hand, may or may not provide such feedback. Some pushbutton switches are designed to be silent, while others may have a audible click, but the main focus of pushbutton switches is more on the mechanical activation of the circuit rather than the tactile feedback.

Design and Size

Tactile switches are generally smaller in size compared to pushbutton switches. They are often used in applications where space is limited, such as in electronic gadgets like mobile phones, remote controls, and small electronic devices. Pushbutton switches, on the other hand, come in a variety of sizes, from small ones used in control panels to large ones used in industrial settings. They may have a more robust design to withstand heavy use and harsh environments.

Functionality

Pushbutton switches can have different functions, such as momentary or latching, as mentioned earlier. Tactile switches are almost always momentary, meaning they only activate the circuit while the button is being pressed. Another difference is that pushbutton switches can often handle higher currents and voltages compared to tactile switches, making them suitable for more powerful electrical circuits.

4. What Are They Used For?

Pushbutton switches have a diverse range of applications due to their simplicity and reliability. In household appliances, they are used to control functions such as starting and stopping a washing machine, turning on a microwave, or adjusting the settings on a coffee maker. In electronic devices like computers, they can be found as power buttons, reset buttons, and buttons for various input functions. In the automotive industry, pushbutton switches are used for controlling features such as power windows, door locks, and interior lights. In industrial control systems, they play a crucial role in operating machinery, starting and stopping production lines, and activating safety functions. They are also used in medical equipment, such as patient monitors and surgical devices, where precise and reliable control is essential.

5. What are the different types of push button switches?

Based on Actuation Type

- Momentary Pushbutton Switches: These are the most common type, where the contacts are only closed (or open) while the button is being pressed. As soon as the pressure is released, the switch returns to its original state. They are used in applications where a temporary activation is required, such as a doorbell or a computer's reset button.

- Latching Pushbutton Switches: These switches have a mechanical latching mechanism that keeps the button in the pressed position until it is pressed again to release. They are used for functions that require a toggle action, such as turning a light on and off.

Based on Contact Configuration

- SPST (Single Pole, Single Throw): This type of switch has one set of contacts that can either be open or closed. It is used for simple on/off control of a single circuit.

- SPDT (Single Pole, Double Throw): SPDT switches have one input terminal and two output terminals. They can connect the input to one of the two outputs, allowing for switching between two different circuits.

- DPST (Double Pole, Single Throw): DPST switches have two sets of contacts that are activated simultaneously. They are used for controlling two separate circuits with a single button press, such as in a stereo system where both the left and right channels need to be turned on or off at the same time.

- DPDT (Double Pole, Double Throw): DPDT switches have two input terminals and two output terminals for each pole. They provide more complex switching options, allowing for the control of two separate circuits with two different switching configurations.

Based on Appearance and Mounting

- Panel-Mount Pushbutton Switches: These are designed to be installed in a panel, such as a control panel of a machine or a dashboard. They come in various sizes and styles, with different button shapes and colors to meet different aesthetic and functional requirements.

- Through-Hole Pushbutton Switches: These are used in printed circuit boards (PCBs) and are mounted by inserting their leads into the holes of the PCB and soldering them. They are commonly used in electronic devices and circuit assemblies.

- Surface-Mount Pushbutton Switches: As the name suggests, these switches are mounted on the surface of a PCB without the need for through holes. They are smaller in size and are suitable for high-density circuit boards, especially in modern compact electronic devices.

6. What are the applications, benefits, and drawbacks of push button switches?

Applications

As mentioned earlier, pushbutton switches are widely used in various industries and applications. In addition to the ones already listed, they are also used in telecommunications equipment, security systems (such as alarm buttons), and consumer electronics like gaming consoles and digital cameras. In the industrial sector, they are essential for controlling heavy machinery, in automation systems, and for safety-critical applications where a quick and reliable switch is needed.

Benefits

- Simplicity and Ease of Use: Pushbutton switches are very easy to operate, even for those with no technical knowledge. A simple press of a button is all that is required to activate or deactivate a function.

- Reliability: Due to their mechanical design, pushbutton switches are generally very reliable, especially when properly maintained. They can withstand a large number of operations without failing, making them suitable for long-term use.

- Versatility: With a wide range of types and configurations available, pushbutton switches can be adapted to almost any application, from low-power electronic circuits to high-power industrial systems.

- Cost-Effective: Compared to other types of switches, such as touch-sensitive or complex electronic switches, pushbutton switches are relatively inexpensive to manufacture and maintain.

Drawbacks

- Mechanical Wear and Tear: Since they are mechanical devices, pushbutton switches are subject to wear and tear over time. The spring may lose its elasticity, and the contacts may become dirty or oxidized, leading to poor conductivity or switch failure. Regular maintenance is required to keep them functioning properly.

- Space Requirements: Some pushbutton switches, especially the larger ones used in industrial settings, may require more space for installation compared to other types of switches, such as tactile switches.

- Limited Aesthetic Appeal in Some Cases: While there are many styles and colors available, in some high-end consumer electronics where a sleek and modern design is desired, pushbutton switches may not be as aesthetically pleasing as touch-sensitive or hidden switches.

Conclusion

Push Button switches are indispensable components bridging human interaction with electronic systems. From turning on a lamp to controlling heavy machinery, their design variations cater to nearly every industry. While tactile switches excel in user interfaces requiring feedback, traditional pushbuttons dominate in high-durability applications.

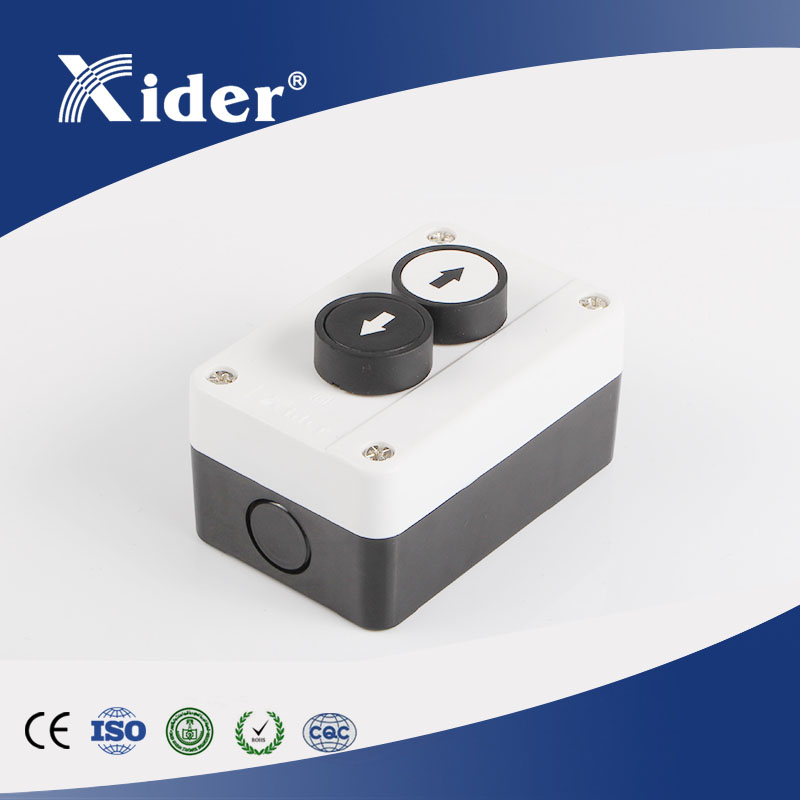

XIDER specializes in the production of low-voltage electrical appliances such as buttons, indicator lights, and control boxes. If you need to purchase push button switches, please contact us.