Harsh industrial environments—such as dusty factories, humid power plants, or workshops with frequent temperature changes—bring unique challenges to push button switches. Many users wonder how to select a switch that operates reliably under these conditions without frequent breakdowns. This article outlines key, practical considerations based on real industrial needs.

Align the Switch with Ingress Protection (IP) Ratings

Not all push button switches are built for harsh settings. The Ingress Protection rating, commonly called IP code, is a critical indicator of a switch's ability to resist dust and water:

For most tough scenarios—like damp power facilities, rainy outdoor traffic control setups, or dusty mechanical workshops—opt for switches with at least an IP65 rating. This level fully blocks dust intrusion and withstands high-pressure water jets from any direction, making it suitable for daily use where moisture and debris are constant.

For special cases requiring temporary water submersion (such as areas prone to accidental flooding), look for switches that can reach IP67 protection with compatible accessories. This rating adds short-term immersion resistance while maintaining full dust protection, though it requires matching accessories to achieve.

Ignoring IP ratings can lead to short circuits or switch jamming, which disrupts production. Choosing the right IP-rated switch based on your environment ensures long-term stability.

Ensure Adaptability to Temperature Fluctuations

Industrial sites often experience wide temperature swings—from high heat in power distribution rooms to freezing cold in outdoor winter conditions.

Avoid switches with narrow temperature ranges. Prioritize options that work stably between -20°C and 60°C, a standard range for industrial-grade switches.

Switches with poor temperature resistance may suffer performance issues: plastic housings might become brittle in low temperatures, or internal metal contacts could overheat in high temperatures.

Prioritize Compliance with Industry-Specific Certifications

Different industries have strict safety standards, and using uncertified push button switches risks violating regulations and creating safety hazards:

For markets in the European Union, the switch must meet CE certification requirements, which cover low-voltage safety and electromagnetic compatibility to ensure safe operation with other industrial equipment.

For applications in China, CQC certification is essential—it verifies that the switch meets national safety and performance standards for low-voltage electrical products.

Certified switches undergo rigorous testing, reducing the risk of malfunctions in harsh environments.

Conclusion

Choosing a push button switch for harsh industrial environments is not about selecting the most expensive option, but about matching the switch's features to your specific setting. By focusing on IP ratings, temperature adaptability, and industry certifications, you can pick a switch that lasts longer and cuts maintenance costs. Always align your choice with the actual conditions of your workplace to keep operations running smoothly.

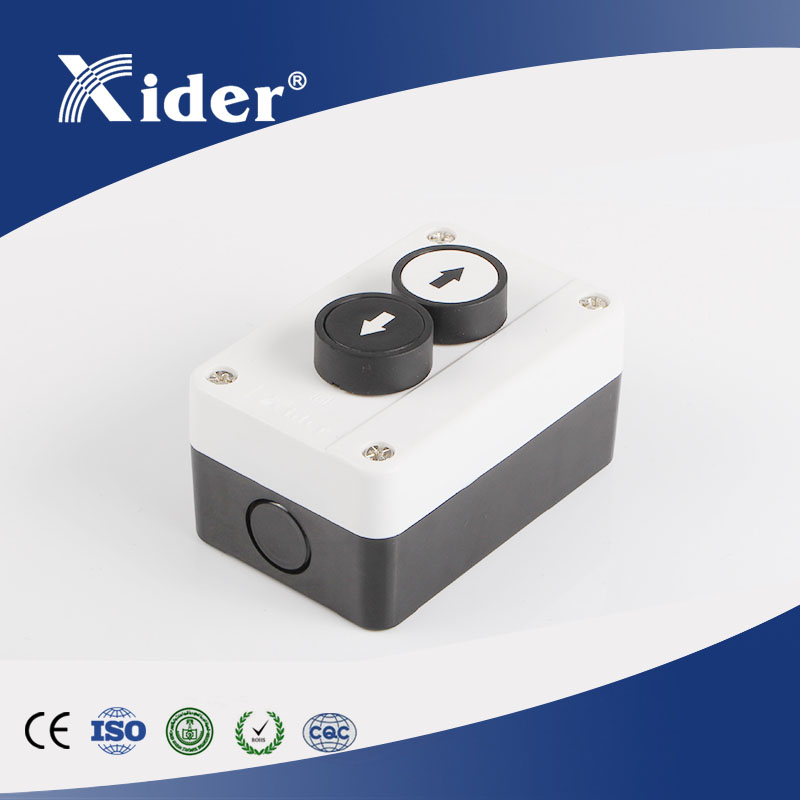

If you need push button switches designed for harsh industrial environments—whether for IP65 protection in daily use or IP67 capability with accessories—you can explore the industrial-grade options on our product page. Each option is engineered to address common environmental challenges, with clear details on protection levels and compliance.