In industries where flammable gases, vapors, dusts, or fibers are present, standard electrical equipment can become a catastrophic ignition source. A simple spark or excessive surface temperature from a regular switch could trigger an explosion. This is where Explosion Proof Push Button Switches become critical safety components. They are specifically engineered to operate safely within these hazardous locations.

1. Definition of Explosion Proof Push Button Switch

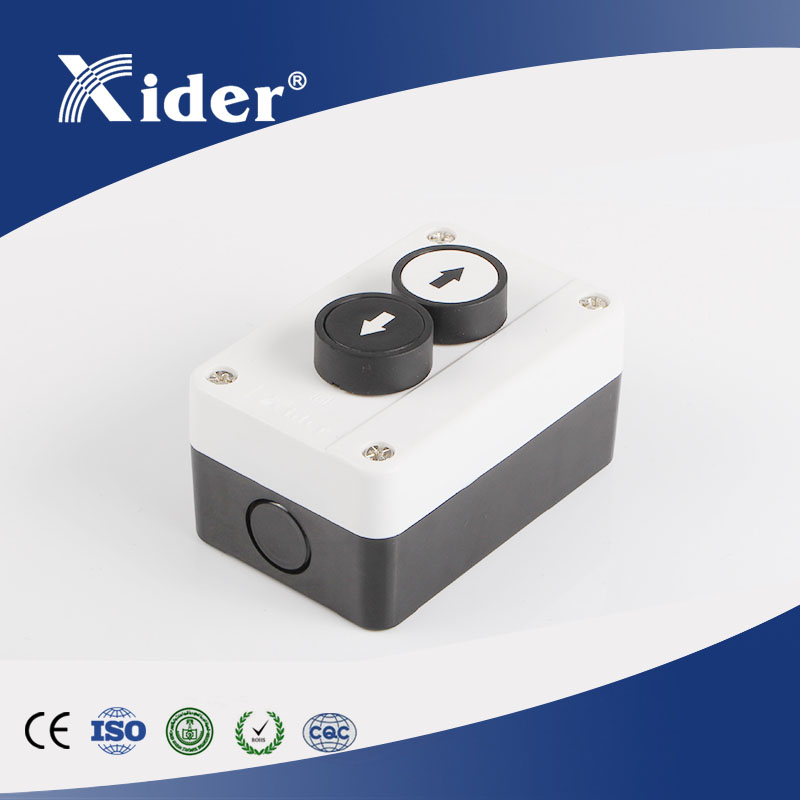

An explosion proof push button switch is a control device specifically designed for use in hazardous environments containing explosive gases, dust, or other flammable mixtures. Through special structural designs and material selections, it effectively prevents internal electrical sparks, arcs, or heat from igniting external explosive substances while ensuring that explosive mixtures cannot enter the switch interior. This allows safe on/off control of circuits in dangerous environments. Its core function is to transmit electrical signals generated by button operations safely while blocking the propagation of explosive energy, safeguarding equipment and personnel.

2. Applications of Explosion Proof Push Button Switch

Petrochemical Industry

In processes such as oil extraction, refining, and chemical production, environments are filled with flammable gases and vapors (e.g., hydrogen, gasoline vapor). Explosion proof push button switches are widely used to control the start/stop of pumps, compressors, mixers, and valve operations, ensuring safe equipment operation and production in hazardous environments. For example, in chemical plant reactor control, operators use these switches to start/stop mixing motors and adjust reaction processes.

Coal Mining and Mineral Industry

Underground coal mines contain high concentrations of methane gas and coal dust, posing significant explosion risks. These switches control ventilators, hoists, conveyors, and other equipment to ensure safe ventilation and transportation systems. They also trigger blasting devices in mining operations, guaranteeing operational safety during explosive procedures.

Pharmaceutical and Food Industry

Some pharmaceutical production processes involve flammable solvents, while food processing plants face risks from explosive dusts like flour or starch. Explosion proof switches control production line start/stop and equipment adjustment, ensuring compliance with safety standards and preventing electrical-spark-induced explosions.

Military and Aerospace Fields

In ammunition production/storage facilities and aerospace ground testing environments, high explosion risks exist. As critical control components, these switches start/stop test equipment and secure system operations, ensuring safety in extreme hazardous conditions.

3. Advantages of Explosion Proof Push Button Switch

High Safety Performance

This is the most prominent advantage. The explosion-proof structure effectively isolates internal arcs/sparks from external explosive gases/dust, preventing explosions. Strict certifications (e.g., IECEx, ATEX) ensure reliable operation in specified hazardous environments, providing robust safety for equipment and personnel.

Adaptability to Harsh Environments

With excellent protection against dust, moisture, and corrosive gases, these switches use durable materials like stainless steel or aluminum alloy with special surface treatments. This extends service life and reduces maintenance costs. For example, they operate stably in wet coal mines or corrosive chemical plants.

Operational Convenience and Reliability

Designed for ergonomic operation, buttons offer comfortable tactile feedback and optimal travel distance for quick, accurate control. Optimized internal structures ensure stable conductivity and minimal contact failures, enhancing equipment reliability and production efficiency.

Flexibility and Versatility

Available in various specifications (voltage, current, explosion protection rating, protection level), they are compatible with different control systems and offer flexible installation options (panel, rail, etc.), adapting to diverse equipment and scenarios.

4. How to Choose Explosion Proof Push Button Switch

Determine Explosion Protection Rating

Select based on the type/concentration of explosive gases/dust and the classification of the hazardous area. Ratings are indicated by symbols like "Ex d IIC T6," where "d" denotes flameproof type, "IIC" applies to Class II, Group C gases, and "T6" means maximum surface temperature ≤85°C. Ensure the rating meets site safety requirements.

Consider Protection Level (IP Code)

IP codes (e.g., IP66, IP67) define dust (first digit) and water (second digit) resistance. Choose based on environmental conditions: IP6X for dusty mines, IP67 or higher for wet/water-sprayed areas.

Clarify Electrical Parameters

Match rated voltage, current, and frequency of the circuit. Ensure contact capacity handles the load to avoid overload failures. Consider contact types (normally open, normally closed, or combined) for control logic needs.

Select Suitable Structure and Installation Method

Choose from single-button, double-button, or indicator-integrated designs based on operation requirements. Installation methods (panel, threaded, flange) should fit available space and facilitate secure, convenient operation.

Prioritize Brand and Quality

Reputable brands offer better quality and after-sales support, with advantages in design, manufacturing, and materials. Verify certification documents (e.g., explosion-proof certificates, test reports) to ensure compliance with safety standards.

Conclusion

Explosion-proof push button switches are not just heavy-duty versions of standard switches; they are sophisticated safety devices engineered on the fundamental principle of explosion containment. Their role in preventing ignition in hazardous locations is indispensable across numerous industries. Selecting the correct switch based on the specific area classification, environmental conditions, required function, and proper certifications is paramount for ensuring the safety of personnel, protecting valuable assets, and maintaining regulatory compliance. Always consult relevant safety codes and standards when specifying and installing this critical equipment.

FAQ

Q: Does an explosion proof push button switch require regular maintenance?

Yes. Despite high reliability, regular maintenance is necessary for long-term safety: clean dust/dirt, check for loose screws, test contact conductivity. Proactive maintenance identifies issues early and extends service life.

Q: Can explosion proof push button switches be used in non-hazardous environments?

Yes. Their excellent protection and reliability make them suitable for ordinary industrial environments with high environmental demands, such as wet or dusty workshops, even without explosive risks.

Q: How to check if the explosion-proof performance is intact?

Verify valid explosion-proof certification marks/certificates. During use, monitor for anomalies like cracked casings, stuck buttons, or arcing contacts. Cease use immediately and inspect/replace faulty units.