In the realm of electrical controls, push buttons and momentary switches are two commonly used components, yet many people often confuse them or are unsure of their specific differences. Understanding the distinctions between these two devices is crucial, whether you're an electronics enthusiast, an engineer, or simply someone interested in how electrical systems work. This article aims to provide a comprehensive exploration of push buttons and momentary switches, delving into their definitions, structures, working principles, and key differences.

1.Definitions and Basic Concepts

1.1 Push Button Switch

Push Button Switch is a control element that switches the circuit on and off by mechanical pressing. Its core feature lies in the operation mode rather than the action characteristics. This type of switch can be divided into the following types according to the mechanical structure:

Latching: After pressing, the switch remains in contact until it is reset by pressing again

Non-Latching: The switch remains in conduction only during the pressing period

Typical applications:

Elevator floor selection button (self-locking type).

Microwave oven start button (non-self-locking type).

Industrial equipment emergency stop switch (special self-locking structure).

1.2 Momentary Switch

Momentary switch is a specific subclass of push button switch, specifically a non-self-locking structure with instantaneous conduction characteristics. Its core parameters include:

Action time: usually 50-200ms

Contact resistance: <50mΩ

Mechanical life: 10^6 operations

Working characteristics:

Keep conduction during pressing.

Automatically reset after release

Available in two configurations: normally open (NO) or normally closed (NC)

2. Comparison of key technologies

|

Comparison dimensions |

Push button switch (self-locking type) |

Momentary switch |

|

Structural principle |

Ratchet locking mechanism |

Spring return structure |

|

Trigger hold |

Maintains the on state |

Only conducts during operation |

|

Reset method |

Releases after a second press |

Automatic spring return |

|

Circuit complexity |

Requires a matching holding relay |

Can directly drive control circuit |

|

Typical power consumption |

Maintaining current 0.5-2A |

Pulse current can reach 5A |

|

Application scenarios |

Power switch/mode selection |

Signal trigger/short-time control |

3.Real-World Applications

When to Use a Push Button

Household appliances (TV power, microwave settings).

Industrial control panels (machine start/stop with lock).

Vehicles (seatbelt reminder reset, cruise control on/off).

When to Use a Momentary Switch

Automotive: Horn, windshield wiper triggers, turn signal cancel.

Electronics: Remote control buttons, keyboard switches, gaming controllers.

Industrial: Emergency stop buttons (momentary activation for safety).

4. Maintenance and optimization suggestions

Push button switch

Contact cleaning: After long-term use, the Push button switch contacts are prone to carbon accumulation or oxidation, resulting in increased contact resistance. They need to be wiped regularly with anhydrous alcohol or special cleaning agents. When they are severely oxidized, they should be lightly polished with fine sandpaper (such as 800 mesh).

Mechanical structure inspection: Check whether the button is stuck when pressed and whether the reset spring is invalid. In industrial environments, mechanical parts need to be lubricated every quarter .

Terminal tightening: It is easy to loosen in a vibrating environment. It is recommended to tighten it according to specifications using a torque screwdriver every year.

Momentary switch

High frequency contact wear: Switches that are operated thousands of times a day need to be checked monthly. It is recommended to use precious metal contacts (such as gold plating) to extend the life.

Shrapnel fatigue detection: After 100,000 times of use, the shrapnel rebound force decreases by more than 20% and needs to be replaced. Quantitative detection can be performed using a spring dynamometer.

Sealing maintenance: Outdoor applications require IP67 or higher protection, and regular replacement of sealing rings (silicone material has a lifespan of about 3-5 years).

conclusion

In the era of intelligent control, traditional switch devices are deeply integrated with sensor technology. When selecting a push button switch, you need to consider load characteristics, operating frequency and environmental factors. The core position of momentary switches in digital control systems will continue to increase. Understanding the essential differences between the two is the cornerstone of building a reliable control system.

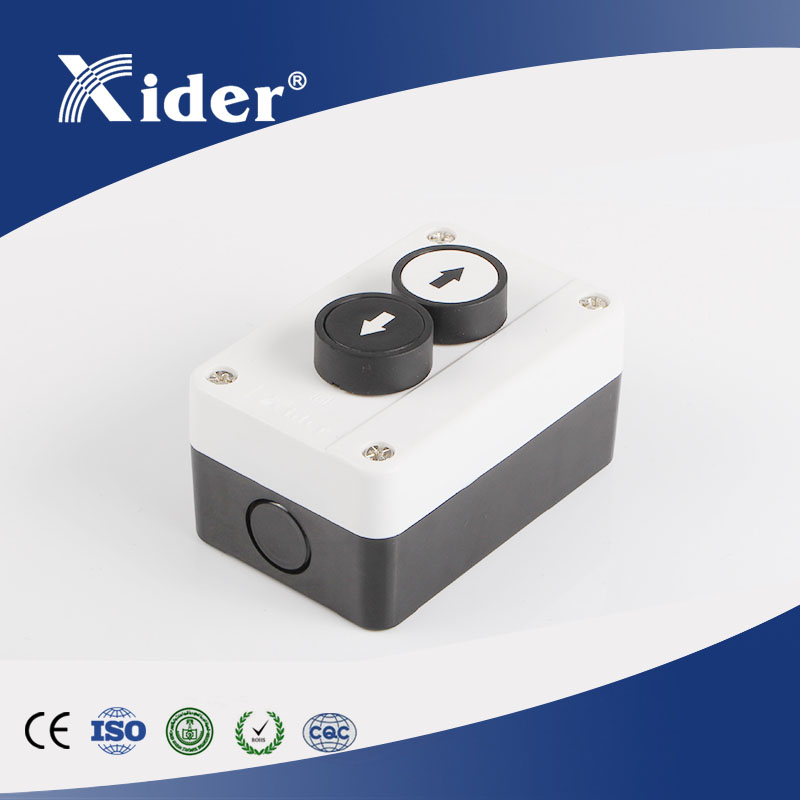

XIDER specializes in the production of low-voltage electrical appliances such as buttons, indicator lights, and control boxes. If you need to purchase push button switches, please contact us.