In industrial fields like power, machinery, and automation, Control Box and Enclosures play a vital role. Many users have questions about their functions, selection, and maintenance. This article will answer these common doubts to help you use them more effectively.

What Are the Main Functions of Industrial Control Box and Enclosures?

1.Protect Internal Components

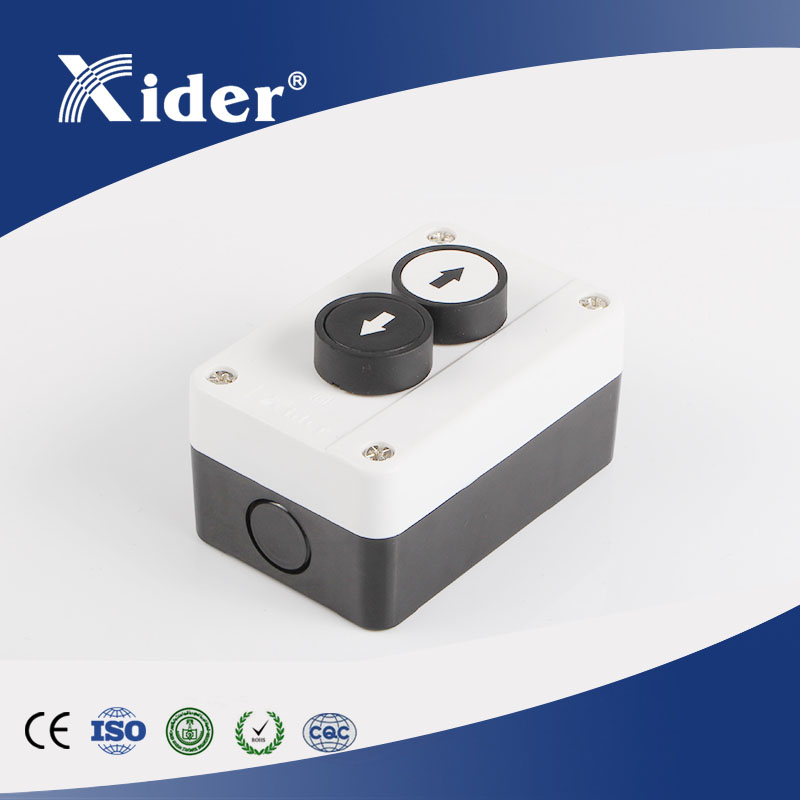

Industrial environments often have dust, moisture, or temperature changes. Control Box and Enclosures act as a barrier, preventing these harmful factors from damaging internal electrical parts (such as buttons and indicators) and ensuring stable operation.

2.Organize Wires and Cables

In industrial systems, multiple electrical components need to be connected. The enclosures provide a centralized space to arrange wires neatly, reducing the risk of wire tangles and making it easier to check and repair later.

3.Ensure Operational Safety

They isolate internal electrical parts from external operators, lowering the chance of electric shock or accidental contact with live components, which is essential for safe industrial operations.

How to Choose Control Box and Enclosures for Different Industrial Scenarios?

1.For Power-Related Scenarios

Power systems involve high voltages. Choose enclosures that can adapt to the voltage requirements of the connected components (e.g., matching the voltage range of low-voltage electrical parts used in power systems) to avoid voltage-related damage.

2.For Machinery-Related Scenarios

Machinery often generates vibrations during operation. Select enclosures with good anti-vibration performance to prevent internal components from loosening due to long-term vibration, which could affect normal function.

3.For Humid or Outdoor Scenarios

Outdoor or humid environments (like some factory areas with moisture) require enclosures with waterproof structures. This prevents water from entering and causing short circuits in internal parts.

What Simple Maintenance Can Extend the Life of Control Box and Enclosures?

1. Regular Cleaning

Dust accumulation on the surface and inside the enclosures can affect heat dissipation and component performance. Wipe the surface regularly and remove dust from internal gaps (when powered off) to keep them clean.

2. Check Sealing Status

Over time, the sealing parts of the enclosures may wear out. Periodically check if the seals are intact. If there are cracks or looseness, replace or repair them in time to maintain the protective effect against dust and moisture.

3. Inspect Internal Wire Connections

During maintenance, check if the internal wires are firmly connected. Loose connections can cause poor contact or overheating. Tighten any loose wires to ensure stable electrical transmission.

Conclusion

Industrial Control Box and Enclosures are not just simple "containers"—they protect components, organize systems, and ensure safety. By understanding their functions, choosing the right type for your scenario, and doing regular maintenance, you can maximize their service life and ensure smooth industrial operations.

If you need industrial-grade Control Box and Enclosures that fit power, machinery, or automation scenarios, you can visit the product page of our website to learn more about the related product series and their specific adaptations to different industrial environments.